Manual Handling - Frequently Asked Questions- Responses

What legislation covers manual handling?

The Safety, Health and Welfare at Work, (General Applications) Regulations 2007, Chapter 4 of Part 2, outline the requirements that must be adhered to in relation to manual handling. The key requirements include:

- Carrying out a manual handling risk assessment of existing manual handling tasks before making an informed decision on what manual handling tasks need to be avoided or reduced.

- Organising tasks to allow the use of mechanical or other means to avoid or reduce the need for the manual handling of loads by employees in the workplace. The hazards can be avoided or reduced through the introduction of appropriate organisational measures for example improved layout of a work area to reduce unnecessary long carrying distances; or the use of appropriate means, in particular mechanical equipment

- Providing instruction and training to relevant staff.

Back to Question List

Do I need to assess every manual handling task?

Manual Handling is a physical activity that takes place in every workplace, and in some cases the activity does not pose problem. However it can be a potential workplace hazard when an employee is required to handled very heavy loads, which could result in a back injury. The type of manual handling activity that needs to be assessed is defined in Regulation 68 of the Safety, Health and Welfare at Work, (General Application) Regulations 2007:

“ Manual Handling involves any transporting or supporting of any load by one or more employees, and includes lifting, putting down, pushing, pulling, carrying or moving a load, which by reason of its characteristics or unfavourable ergonomic conditions, involves risk, particularly of back injury, to employees.”

These characteristics or unfavourable ergonomic conditions are the risk factors which are outlined in Schedule 3 of the 2007 Regulations and have the potential to cause harm.

The picture below illustrates a manual handling activity that would need to be addressed as part of the manual handling risk assessment process. A characteristic of the load that involves risk is the barrel weighing 80kg. An unfavourable ergonomic condition is the physical strain involved in having to lift such a load.

Back to Question List

Why does manual handling result in a risk of injury or ill health?

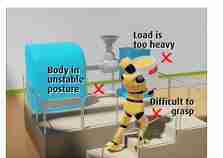

Many of the problems that cause back pain are the result of injury and damage to a disc. Bending over results in pressure on the discs, and may also cause a disc to bulge backward towards the spine. Twisting and bending together put the greatest stress on the spine, especially on the discs, and are examples of work conditions that increase the risk of back injury. The picture below illustrates some examples of work conditions that involve risk:

Back to Question List

How do I carry out a risk assessment of manual handling tasks?

Refer to the Manual Handling Risk Assessment Video Series for examples how to conduct a risk assessment of a manual handling task:

- Stage 1: This stage involves collecting information on how the task is performed and identifying the key stages in the task. This should be a team effort involving consultation with those that normally do the job. You (or the person carrying out the assessment) should have a thorough practical understanding of the type of manual handling tasks being carried out.

- Stage 2:

Collect all technical details to include information on the load weight, load size, number of manual lifts, general information on postures observed and the work environment

- Stage 3:

Identify the problems or risk factors. This should be completed by making reference to the Risk Factors detailed in the Health and Safety Authority publications titled Management of Manual Handling in the Workplace or the Guide to the Safety, Health and Welfare at Work (General Application) Regulations 2007: Chapter 4 of Part 2: Manual Handling.

- Stage 4:

Identify what improvements you can put in place. Once you have identified the risk factors, it is necessary to investigate potential solutions. Examples of efforts that should be made include using mechanical aids, organising the work activity to reduce the need for travelling long distance or reducing the size of the load. Clearly document the rationale for deciding on the appropriate control measure, outlining why other control measures were not possible and how the suggested control measure will avoid or reduce the risk of injury. Employees should be consulted as part of this process and where a new work activity is introduced it needs to be assessed to ensure that it does not introduce new hazards.

- Stage 5:

Review the effectiveness of the control measures: Effectiveness is the degree to which the control measures have avoided or reduced the risk of injury.

Back to Question List

Are there appropriate guidance documents to refer to for advice and direction on how to comply with the

Manual Handling of Loads Regulation?

There are four guidance documents available in relation to the Manual Handling of Loads Regulation

Back to Question List

Is there any guidance document I can refer to for information on the Manual Handling Training System?

Download the Guide on the Manual Handling Training System - 2010 Revision

Back to Question List

What is the current guidance on course content of a manual handling training course for employees?

The Health and Safety Authority prepared Manual Handling Training Guidance and a framework for Manual Handling Training in Ireland. (i.e. The FETAC Level 6 Manual Handling/People Handling Standards).

As part of this guidance the FETAC Level 6 was the level agreed for manual handling instructors and systems are in place for instructors to achieve this qualification.

The framework for manual handling training includes the following:

Manual Handling Training at workplace level should be delivered by a FETAC Level 6 Manual Handling Instructor

The content of training programmes to be delivered by an instructor should meet the requirements set out in Appendix 3 of the H.S.A. guide titled “Guidance on the Manual Handling Training System – 2010”.

http://www.hsa.ie/eng/Publications_and_Forms/Publications/Manual_Handling_and_Musculoskeletal_Disorders/Guidance_on_the_Manual_Handling_Training_System_-_2010_revision.html

It is our view that manual handling training needs to be carried out in line with these requirements to ensure that employees have adequate and appropriate knowledge or training.

This manual handling framework offers guidance to employers and other duty holders on what is considered best practice. The employer can use other means to comply with the law, provided he/she is able to prove that they are equivalent to the Irish Guidance on Manual Handling Training and afford the same level of protection

Back to Question List

How often do employees need refresher training?

Refresher training will be at intervals not more than every three years and when there is any major change in the work involved or equipment used or when an employee is transferred to another activity requiring different loads to be handled.

Back to Question List

Are there minimum requirements for the duration of manual handling training courses for employees?

The Health and Safety Authority do not specify time duration for manual training courses. The duration of the training course should be tailored to the number and complexity of the handling procedures being taught. The employers must satisfy themselves that the instructor who delivers the course covers the relevant topics comprehensively.

Back to Question List