ATEX

ATEX generally refers to the hazard of explosive atmospheres occurring in the workplace due to the presence of flammable gasses or combustible dust mixed in air, which can give rise to the risk of explosion.

From an electrical perspective it is well known that equipment such as light fittings, switches, motors or virtually any type of electrical apparatus may cause sparking or could generate In addition, static electricity built up on a person, clothing or item may discharge with a spark. In either case a spark could ignite an explosive atmosphere with potentially devastating results. Therefore if an explosive environment is unavoidable in a workplace, suitably rated and protected electrical equipment must be used to prevent the possibility of ignition from a spark, or other source of heat. In addition special precautions such as anti-static clothing and shoes may be necessary to prevent the possibility of a static electrical discharge potentially igniting a flammable gas or combustible dust.

Hazardous areas are classified into three categories for gases and three categories for dusts:

| Zone Classification for Gases |

| Zone 0 | That part of a hazardous area in which a flammable atmosphere is continually present or present for long periods. |

| Zone 1 | That part of a hazardous area in which a flammable atmosphere is likely to occur in normal operation. |

| Zone 2 | That part of a hazardous area in which a flammable atmosphere is not likely to occur in normal operation and, if it occurs, will exist for a short period |

Any area that is not classified as Zone 0, 1 or 2 is deemed to be non-hazardous, as flammable atmospheres are not expected to be present. Special precautions for the construction and use of electrical apparatus or for the control of non-electrical ignition sources are therefore not required although such an area may still be part of a greater restricted area.

The zoning above does not cover areas where combustible dusts may be present but a three-zone approach (Zones 20, 21 and 22) has now also been adopted for dusts. For further details see the IEC 61241 series.

| Zone Classification for Dusts |

Zone 20 | A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is present continuously, or for long periods or frequently for short periods. |

Zone 21 | A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is likely to occur occasionally in normal operation. |

Zone 22 | A place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only. |

From 1 November 2007, Part 8 of the General Application Regulations 2007 re-transposes the (ATEX) Directive 1999/92/EC of the European Parliament and of the Council of 16 December 1999 regarding the risk from explosive atmospheres and the risks from fire and explosion arising from flammable substances stored or used in the workplace. These Regulations govern occurring general management precautions to be taken in the event of the possibility of an explosive atmosphere in the workplace. Part 8 of the General Application regulations 2007 also replaces the Safety, Health and Welfare at Work (Explosive Atmospheres) Regulations 2003 (S.I. No. 258 of 2003), which are revoked from that date.

The supply of equipment to Zones 0, 1 or 2 or Zone 20,21 or 22 is regulated by SI No 230 of 2017 European Union (Equipment and Protective Systems for use in Potentially Explosive Atmospheres) Regulations 2017.

The link below shows a detailed guide to the concept of the ATEX directive as prepared by the European Commission and considered European perspective.

EC detailed guide to ATEX

Because of the need to prevent ignition sources in potentially explosive atmospheres, special fittings are used which prevent contact between ignition sources and the explosive atmosphere or which limit the energy which can be emitted below the energy level needed to cause an explosion.

Figs 7(a), (b),(c) & (d) below shows typical examples of electrical apparatus for use in explosive atmospheres.

Fig 7(a) Category 1 Torch |

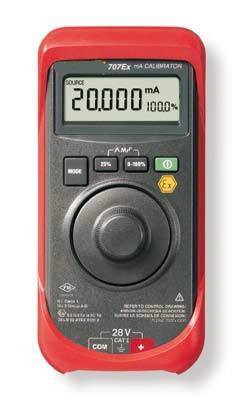

Fig 7 (b) Category 2 Calibration Meter |

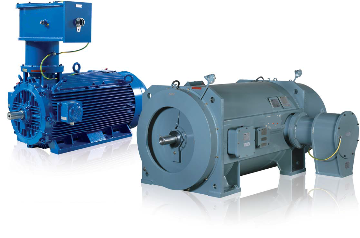

Fig 7(c) Category 2 Flameproof Motors |

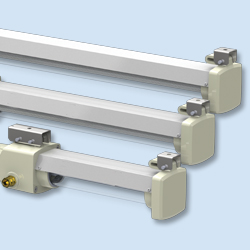

Fig 7(d) Category 2 Fluorescent Light Fittings |

In addition to the electrical fittings, the entire electrical installation in a potentially explosive atmosphere must be undertaken by competent personnel who have experience and training in electrical installations in potentially explosive atmospheres.

Regulations made under the 1972 Dangerous Substances Act (No. 10 of 1972) require inspection, testing and reporting on the electrical installation in

- retail and private petroleum stores at least every 3 years,

- petroleum bulk stores at least every 12 months and

- oil jetties at least every 15 months.

Additional checks over and above a standard installation are required for all electrical installations with potentially explosive atmospheres.

The following is an example of a specimen Completion Certificate that could be used for electrical installations

Explosive-Atmospheres-Sample-Cert

ATEX Regulations - Frequently Asked Questions

ATEX Delivery Guide