CONCEPTS |

Concepts Used in ATEX |  |

|

A Potentially Explosive Atmosphere is a mixture with air under atmospheric conditions of flammable substances in the form of gas, vapour, dust, fibres or flyings which, after ignition, permits self sustaining propagation.

Flammable (explosive) limits:

Before a fire or explosion can occur, three conditions must be met simultaneously. A fuel (i.e. combustible gas) and oxygen (air) must exist in certain proportions, along with an ignition source, such as a spark or flame. The ratio of fuel and oxygen that is required varies with each combustible gas or vapour. The minimum concentration of a particular combustible gas or vapour necessary to support its combustion in air is defined as the Lower Explosive Limit (LEL) for that gas. Below this level, the mixture is too “lean” to burn. The maximum concentration of a gas or vapour that will burn in air is defined as the Upper Explosive Limit (UEL). Above this level, the mixture is too “rich” to burn. The range between the LEL and UEL is known as the flammable range for that gas or vapour.

Zones: |  |

|

Overview:

Zones are used to define the frequency of occurrence and the duration of the presence of flammable materials. The likelihood of the hazard being present in flammable concentrations will vary from place to place. A location very close to an open source of hazard will have a high likelihood of a flammable atmosphere. On the other hand, outside a flanged pipe containing a flammable liquid, the likelihood of a flammable atmosphere being present is much lower since it will only occur if the flange leaks. Rather than work with an infinite range of possibilities, zones are defined as follows:

Gases and Vapours.

There are three zones for gases and vapours:

Zone Gases & Vapours | Definition |

| 0 | An area in which an explosive gas atmosphere is present continuously or for long periods or frequently |

| 1 | An area in which an explosive gas atmosphere is likely to occur under normal operation occasionally |

| 2 | An area in which an explosive gas atmosphere is not likely to occur under normal operation but, if it does occur, will persist for a short period only |

Dusts.

There are three zones for dusts:

Zone - Dust | Definition |

| 20 | A place in which an explosive atmosphere, in the form of a cloud of dust in air, is present continuously, or for long periods or frequently |

| 21 | A place in which an explosive atmosphere, in the form of a cloud of dust in air, is likely to occur in normal operation occasionally |

| 22 | A place in which an explosive atmosphere, in the form of a cloud of dust in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only |

Gas Groups:

Gases and vapours are categorized in terms of their ignition energy or the maximum experimental safe gap (in respect of flameproof protection). This categorization leads to the Gas Groups. Group IIC is the most severe group. Hazards in this group can be ignited very easily.

Gas Group | Test Gas |

I(mining) | Methane (firedamp) |

IIA | Propane |

IIB | Ethylene |

IIC | Hydrogen |

Dust Groups:

Combustible dusts & fibres in dangerous quantities are classified as hazardous and divided into three zones according to level of risk

Dust Group | |

IIIA | Combustible flyings |

IIIB | Non-conductive dust |

IIIC | Conductive dust |

Overview:

Hazardous area apparatus is classified according to the maximum surface temperature produced under fault conditions at an ambient temperature of 40°C, or as otherwise specified. The standard classifications are as follows:

Temperature Classification:

Temperature Class | Maximum Surface Temperature |

| T1 | 450°C |

| T2 | 300°C |

| T3 | 200°C |

| T4 | 135°C |

| T5 | 100°C |

| T6 | 85°C |

EPL's (Equipment Protection Levels) and Zones: |

Graphic of EPL's and how they relate to Zones

There are varying types of equipment that can be used within these zones to ensure that the potential for an explosion is removed or greatly reduced. This equipment must be designed and manufactured in accordance with particular construction parameters known as protection concepts. Essentially these concepts fall under four main methods. These methods are detailed below along with a brief description of some of the concepts:

|

Ex d Flameproof |  |

The equipment that may cause an explosion is contained within an enclosure which can withstand the force of an explosion and prevent transmission to the outside hazardous atmosphere. This method of protection also prevents the hazardous atmosphere from entering the enclosure and coming into contact with equipment. Suitable for: - Zone: 1 and 2

- Category: 2G and 3G

- EPL: Gb and Gc

|

Ex e Increased Safety |  |

Precautions are applied to the installation to ensure increased security against the possibility of excessive temperatures and sparks from electrical equipment. Equipment that normally causes sparks is excluded from use within this method of protection. Suitable for: - Zone: 1 and 2

- Category: 2G and 3G

- EPL: Gb and Gc

|

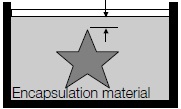

Ex m Encapsulation |  |

A protection concept whereby equipment that could potentially cause an ignition is encapsulated within a compound or resin so as to prevent contact with the explosive atmosphere. The concept also limits the surface temperature of the equipment under normal operating conditions. Ex ma suitable for: - Zone: 0, 1, 2, 20, 21 and 22

- Category: 1G, 2G, 3G, 1D, 2D and 3D

- EPL: Ga, Gb, Gc, Da, Db and Dc

Ex mb suitable for: - Zone: 1, 2, 21 and 22

- Category: 2G, 3G, 2D and 3D

- EPL: Gb, Gc, Db and Dc

Ex mc suitable for: - Zone: 2 and 22

- Category: 3G and 3D

- EPL: Gc and Dc

|

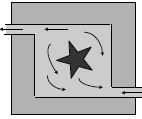

Ex p Pressurised |  |

One process ensures that the pressure inside an enclosure is sufficient to prevent the entrance of a flammable gas, vapour, dust, or fibre and prevent a possible ignition. Another process maintains a constant flow of air (or an inert gas) to dilute to take away any potentially explosive atmosphere. Ex pxb and Ex pyb are suitable for: - Zone: 1 and 2

- Category: 2G and 3G

- EPL: Gb and Gc

Ex pzc is suitable for: - Zone: 2

- Category: 3G

- EPL: Gc

Ex pD is suitable for: - Zone: 21 and 22

- Category: 2D and 3D

- EPL: Db and Dc

|

Ex o Oil Immersion | |

All equipment that has the potential to arc and potentially cause an ignition is immersed in a protective liquid or oil. The oil provides an insulating method to prevent ignition. Suitable for: - Zone: 1 and 2

- Category: 2G and 3G

- EPL: Gb and Gc

|

Ex q Powder Filling | |

All equipment that has the potential to arc is contained within an enclosure filled with quartz or glass powder particles. The powder filling prevents the possibility of an ignition. Suitable for: - Zone: 1 and 2

- Category: 2G and 3G

- EPL: Gb and Gc

|

Ex n Non-Sparking |  |

A type of protection where precautions are taken so that electrical equipment that has the potential to arc is not capable of igniting a surrounding explosive atmosphere. This can be further categorised as follows: Ex nA -Where components used in construction are non-sparking Ex nC -Where components used in construction are non-incentive Ex nR – Where components used are tightly enclosed to restrict the breathing and prevent ignition Ex ic -Where components used in construction do not contain enough energy to cause an ignition. Suitable for: - Zone: 2

- Category: 3G

- EPL: Gc

|

Ex s Special |

This method of protection, as its name indicates, has no specific parameters or construction rules. In essence it is any method of protection which can provide a pre-determined level of safety to ensure that there is no potential for an ignition. As such it does not fall under any specific protection method and may in fact be a combination of more than one. Suitable for: - Zone: 0, 1 and 2

- Category: 1G, 2G and 3G

- EPL: Ga, Gb and Gc

|

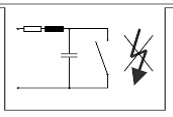

Ex i Intrinsic Safety |  |

A protection concept in which the electrical energy within the equipment is restricted to a level which is below that what may cause an ignition or to limit the heating of the surface of the equipment. There are two main sub types to Ex i protection, these being “ia” and “ib”. Type “ia” protection allows for the occurrence of two faults during operation Type “ib” protection allows for the occurrence of one fault during operation. Ex ia suitable for: - Zone: 0, 1, 2, 20, 21 and 22

- Category: 1G, 2G, 3G, 1D, 2D and 3D

- EPL: Ga, Gb, Gc, Da, Db and Dc

Ex ib suitable for: - Zone: 1, 2, 21 and 22

- Category: 2G, 3G, 2D and 3D

- EPL: Gb, Gc, Db and Dc

Ex ic suitable for: - Zone: 2 and 22

- Category: 3G and 3D

- EPL: Gc and Dc

|

Ex 'ta', 'tb' and 'tc' Protection by enclosures |

The enclosure is sealed so tight, that no combustible dust can enter. The surface temperature of the external enclosure is limited. Ex ta suitable for: - Zone: 20, 21 and 22

- Category: 1D, 2D and 3D

- EPL: Da, Db and Dc

Ex tb suitable for: - Zone: 21 and 22

- Category: 2D and 3D

- EPL: Db and Dc

Ex tc suitable for: - Zone: 22

- Category: 3D

- EPL: Dc

|