Slip Risk Assessment and Prevention

- Every working day in Ireland more than three people are hurt in work slips (excluding trips and falls)

- 23% of those who slip are off work for over one month

- People generally slip on contaminated surfaces/ footwear

- People generally do not slip on clean dry surfaces

This web page provides simple step-by-step advice on how to manage, assess and prevent work slips. The advice targets fixed level places of work. See our separate advice on Safer Stairs and Steps and work vehicles

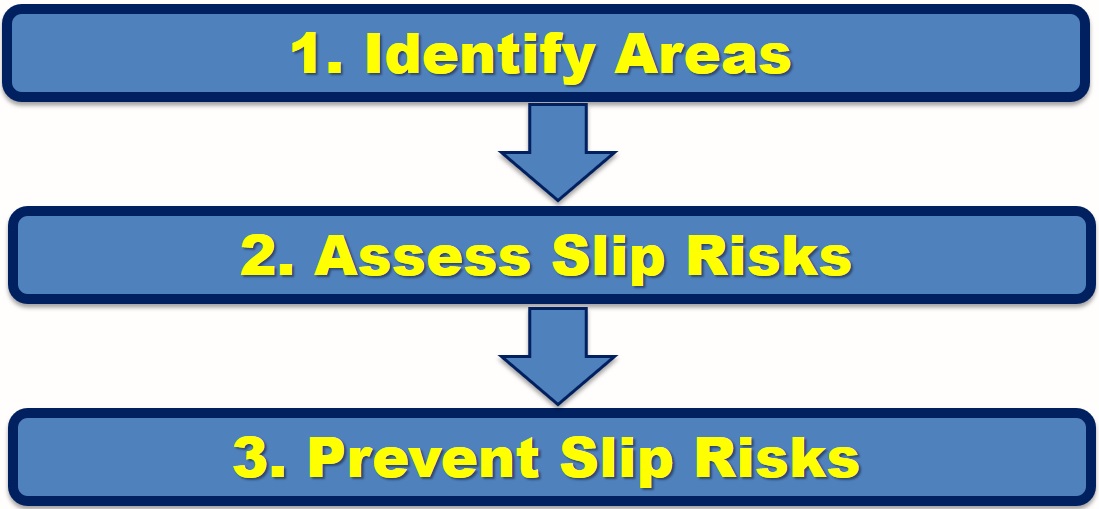

SLIP RISK ASSESSMENT AND PREVENTION PROCESS

The Safety, Health and Welfare at Work Act requires risk assessment. The Slip Risk Assessment and Prevention Process can be completed with three key steps.

The two-page Slip Prevention and Risk Assessment Tool Sample, or a similar document, can help prioritise areas for attention and record and track progress

STAGE 1 IDENTIFY AREAS

A slip risk assessment process could start by identifying manageable areas of a workplace, for example,

- Area – a logical work area, e.g. bathroom, entrance

- Worksite – this may simply be the address of the worksite

- Pedestrian Surface – in as much detail as possible including the condition of the surface, e.g. heavily worn blue linoleum

- Date

To complete a workplace slip-risk assessment, combine the individual slip-risk assessments using a Mapping Tool or using a spreadsheet or some equally effective solution.

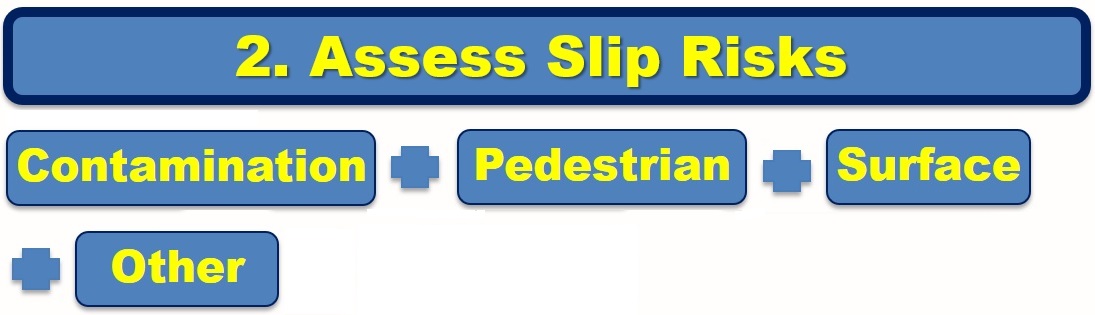

STAGE 2 ASSESS SLIP RISKS

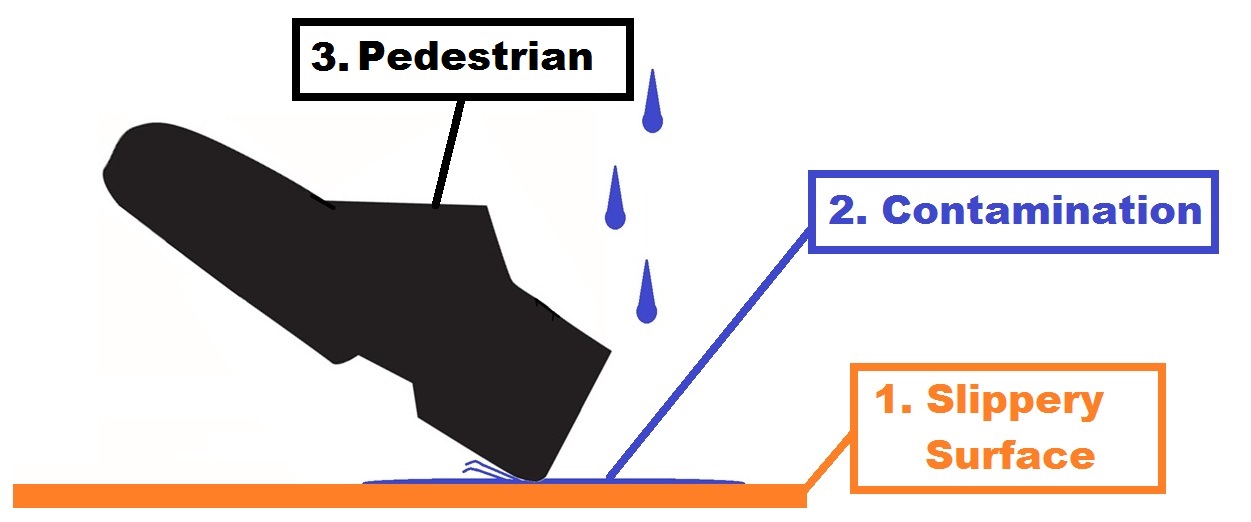

Slips generally involve three Slip Risk Factors

Slip-risks can be categorised as Low, Medium or High Risk.

5. Contamination

See our advice on identifying contamination slip-risks from

6. Pedestrian

Potential pedestrian slip-risk should be risk assessed including access, footwear and behaviour

Pedestrian Access

Pedestrian access can be considered including important questions like

- are there peak times?

- are pedestrians familiar with the area?

- is the access by the most direct route?

- if not, check if any shortcuts are being used

- are access routes clearly marked?

- are safe walkways created when needed, e.g. through ice/snow?

- are additional controls in place at entrances during rain, if required?

- are floors cordoned off for wet cleaning?

Pedestrian footwear can mitigate against or contribute to slip-risk. Assess the slip resistance of employee footwear (especially slip resistance of the heels) using our advice on slip-resistant footwear.

Also consider the ability to control footwear in the workplace. Has slip-resistant footwear been identified as required PPE?

Pedestrian Behaviour

It may be helpful to observe behaviour patterns to identify any behaviours of concern. Pedestrian behaviour can be considered including important questions like

- is there evidence of distracted walking, e.g. using mobile devices/ phones/ music?

- are people rushing?

- are people carrying items?

- have people received training?

- are any high risk areas identified?

- are people wearing slip-resistant PPE footwear if required?

7. Slippery Surface

Regulations 9, 23, 99 and 105 of the General Application Regulations outline that pedestrian surfaces should be not slippery. In limited cases, there may be a justifiable reason for intentionally slippery surfaces, for example, on a van loaded by sliding the load, anti-climb paint. In these cases, contamination and pedestrian risk factors must be very carefully risk assessed and warning signs and slip-resistant footwear are likely to be required.

Slips on a level typically occur on contaminated harder surfaces and not on soft surfaces such as carpets. Slippery Surface locations include wet slippery surfaces, walkways, entrances/ exits and bathrooms. Potential slippery surface slip-risks should be risk assessed including history, data and measurements

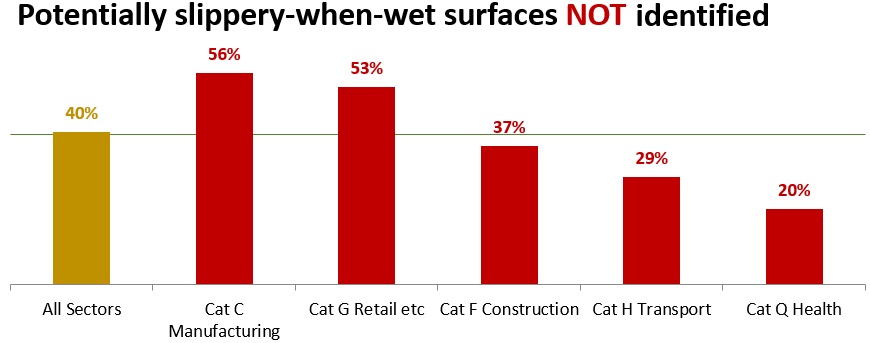

| In 2018, 2019 and 2020, Inspectors found in 40% of over 1,700 workplace visits, that the risk assessment had NOT identified pedestrian surface(s) that could be slippery-when-wet. The rate was higher in Manufacturing and Retail and lower in Construction, Transport and Healthcare. |

Pedestrian Surfaces Slip History

The history of incidents and near-slips may indicate that a surface is slippery. Check for a history of slips or near-slips, or other evidence that pedestrians slip on the surface. Check with workers if the surface is slippery, not just when dry but also when contaminated. Employees should be actively asked for their views – "does the surface feel slippery underfoot when dry or wet/ contaminated?"

Pedestrian Surfaces Slip Data

The slip-resistance of a pedestrian surface is likely to change because of traffic, wear and tear, contamination and cleaning. The Safety, Health and Welfare at Work Act requires designers, manufacturers, importers or suppliers of articles to provide or arrange for adequate information to ensure safe use.

Information on claimed and actual slip-resistance may be available in

Other reports also rate various floor types as high, medium or low slip-risk. Helpful reports include*:

* This list is non-exhaustive and in no particular order

See our advice on measuring slip resistance

8. Other Factors

Factors other than contamination, pedestrians and the slippery surfaces could affect slip risk.

Six sectors account for 55% of the workforce but 81% of slips, trips and falls (STF) - these are the “Big Six” sectors. Some areas typically associated with Slips, Trips and Falls (STF) in the “Big Six” sectors can be identified by looking at causes for each sector, for example,

Transport – walkways and yards

Public Admin –walkways, entrances/exits and car parks

Healthcare – walkways, bathrooms and entrances/exits

Industry – walkways and entrances/exits

Construction – walkways and entrances/exits

Retail - entrances/exits, cold rooms and shop aisles

Some factors may be particular to individual workplaces. Consider any other factors that could affect slip risk such as hot oil, level changes, etc

STAGE 3 PREVENT SLIP RISKS

For Slippery Surface Controls, to check the improvement, assess slip-resistance before and after treatment, and monitor periodically thereafter to ensure continued slip-resistance. New cleaning regimes are likely to be required with new, treated, or resurfaced pedestrian surfaces.

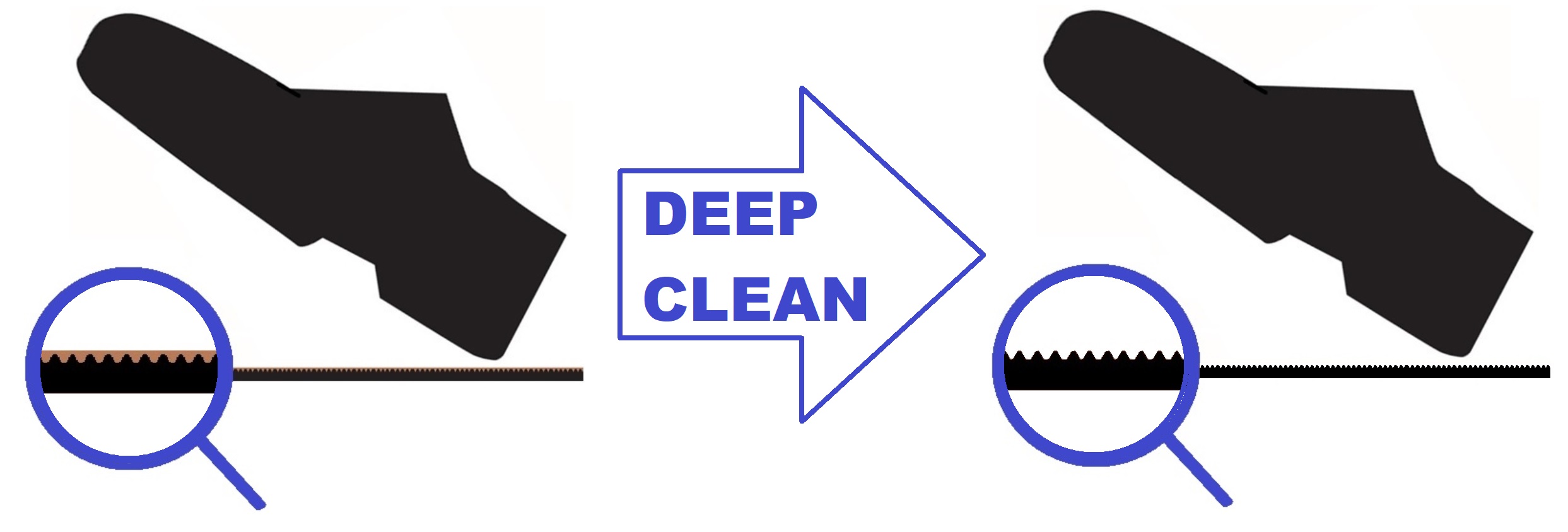

9. Slippery Surface Deep Cleaning

Where a surface originally had good slip-resistance, it may be possible to restore that initial good grip with a thorough deep clean. Slip-resistance may have been reduced because of a build-up of dirt, detergent, polish, material from shoe soles. For cleaning and deep cleaning it's important to use the correct chemical, physical and thermal energy. Consider the manufacturers advice on floor cleaning for that particular floor. Deep cleaning is likely to be needed before further surface treatments.

The UK Timber Decking and Cladding Association (TDCA) advise "The key factor in preventing slippery decking is to ensure that the deck surface is kept clean and surface deposits such as mildew, algae and fine mosses are kept at bay." Deep cleaning is likely to be required before most surface treatments/ resurfacing. For effective deep cleaning, use the correct chemical, physical and thermal energy.

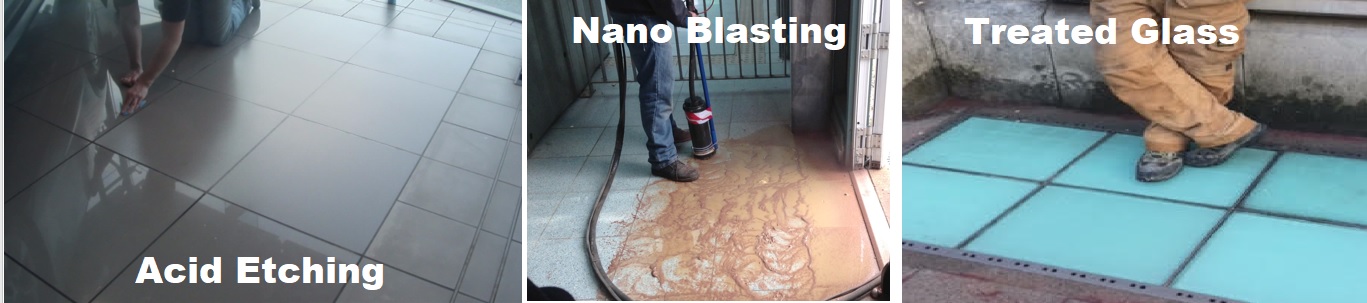

10. Slippery Surface Treatment

For slippery surface treatments consider our advice on “Slip Resistance” under Selecting Slip Resistant Pedestrian Surfaces, for example, specify the expected slip-resistance and anticipated life, allowing for wear and tear. In most cases, a new cleaning regime may be required

Chemical or physical treatments to improve slip-resistance include*:

* This list is non-exhaustive and in no particular order

11. Slippery Surface Resurfacing

For slippery surface resurfacing consider our advice on “Slip Resistance” under Selecting Slip Resistant Pedestrian Surfaces, for example, specify the expected slip-resistance and anticipated life, allowing for wear and tear. Choose and apply new surfaces carefully. In most cases, a new cleaning regime may be required

Resurface the pedestrian surface with a material that provides a low slip-risk. Methods of resurfacing a slippery surface include*:

- Anti-slip coating - for example, the UK TDCA advise about "anti-slip decking products that can be fitted retrospectively [and] generally fix into the grooves or ...the surface."*

- Anti-slip strips/ patches - need to be monitored and replaced when worn*

- Anti-slip film on glass floors*

- Mats* are only appropriate in limited situations. Mats may be a source of contamination and can also present a trip hazard if the edges are raised and/or not properly secured in place*

* This list is non-exhaustive and in no particular order

12. Spills Contamination Controls

See our advice on controls for spills including how to

13. Cleaning Contamination Controls

See our advice on controls for cleaning including how to

- Communicate

- Replace wet cleaning where possible

- Reschedule to low traffic times

- Equip to allow safer cleaning, e.g. cordon facilities, equip to allow proper dilution of cleaning chemicals

- Segregate damp and drying surfaces to prevent pedestrian access

14. Ice Contamination Controls

See our advice on controls for ice slips including

15. Pedestrian Access Controls

Preventing or restricting pedestrian access in a clear planned matter can be very effective in reducing slip risks, for example

- close a slippery surface work area that is no longer necessary

- increase safeguards at identifiable peak times

- prevent access to a floor or areas of a floor that are wet/damp/drying (like cordoning floors for wet cleaning)

- create safe channels through dangerous slippery surfaces (like clearing snow and ice, safe channels at wet entrances)

- clearly identify safe paths with signs, safety colours, barriers

- clearly identify hazards with warning stripes

16. Pedestrian Footwear Controls

See our advice on slip-resistant footwear controls.

17. Pedestrian Behaviour Controls

Define clear controls for hazardous behaviours such as rushing, distracted walking and manual handling.

Provide advice and training on safeguards and controls. Signs and safety colours may be useful to back up training and instructions, and to identify high-risk areas.

18. Other Controls to Prevent Slips

Put controls in place to tackle other risks identified in the risk assessment

The two-page Slip Prevention and Risk Assessment Tool Sample, or a similar document, can help track and record progress

Slippery Surface Case Studies

HSE UK provides useful advice on improving slip resistance. The advice on acid-etching (and hydrofluoric acid) is important. HSE UK has a wide range of case studies including cleaning, matting, design, maintenance and training. HSL advise about an abattoir that reduced slips costs from £207,800 to £136,000 over three years by “clear” floor specifications, “matched” footwear, monitoring and removal of chequerplate.

The Napo animated video "Shining example" (1 minute, 8 seconds) shows the problem with choosing a floor surface based solely on how it looks