Safety Alert – Bale Stacking in the Waste Sector

The Health and Safety Authority (HSA) is issuing an alert to the waste sector regarding risks associated with the storage and staking of baled waste material. Improper stacking techniques, damaged or irregular shaped bales, and uneven weight distribution can lead to a stack collapse, causing serious and/or fatal injuries. A previous HSA Alert was issued on this hazard in 2019.

Factors affecting stack stability

- The stacked material may be unstable from the outset due to poor stacking techniques, including factors such as uneven weight distribution, improper alignment of bales, and/or overstocking.

- The size, weight, shape and density of the bales will have an impact on the stability of the stacked material. Such variations call for different stack configurations and methods of stacking.

- The type of material in the bale will need to be considered when choosing how the baled material is to be stacked.

- Environmental conditions can degrade the baled material and weaken the stability of the stack.

- Placing heavy or large bales on the top of smaller or lighter bales can cause a stack to become unstable.

- Overloading or loosely strapping bales of cardboard, aluminium cans, etc. can cause bale straps to break or bales to come apart, weakening stacks and risking collapse. Straps can also deteriorate over time if exposed to adverse weather (if stored outdoors).

Corrective Actions

Employer Duties

The employer must:

- Carry out a risk assessment to identify the risks associated with the storage and stacking of bales. The risk assessment should include, but not be limited to an assessment of the stack height, configuration, etc.

- Document a safe system of work and method statement for bale handling, stacking and de-stacking.

- A written procedure should be put in place to deal with stacks that have become unstable or are at risk of collapse.

Control Measures

The employer must put in place suitable and sufficient control measures which could include the following:

- Material is stacked on level ground that is free from debris and is properly drained.

- Construct a stack of baled material which is of similar material, size and weight.

- Bigger heavier bales should be stacked on the bottom with smaller lighter bales on top.

- Damaged or irregularly shaped bales should be stored separately and not stacked.

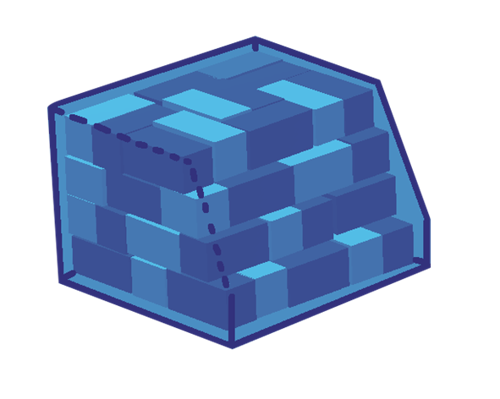

- Ideally the stacked bales should be contained on three sides by a wall or other barrier designed to withstand the weight. Bales on the open side of this stack should be stepped back. See figure 1.

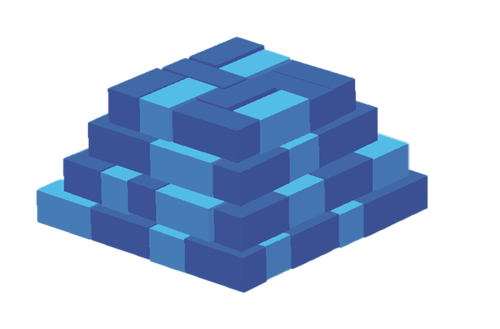

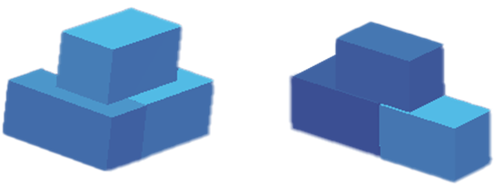

- In the case of a freestanding stack, avoid stacking bales vertically one of top of the other. They should be stacked in a pyramid formation. See Figure 2 and 3.

- Bales should be interlocked as the stack is being constructed which will improve stability.

- Protect the stack from being struck by moving vehicles. Where a vehicle hits a stack, causing instability, the stack should be de-stacked and rebuilt in a stable configuration.

- Put a traffic management plan in place that focuses on segregating vehicle movements from pedestrians.

- An appropriate and clearly indicated exclusion zone should be put in place around the danger area of the bale storage area to prevent unauthorised access and to protect pedestrians from the risk of falling bales.

- Appropriate vehicles should only be used for stacking and moving the bales. The vehicles should be fitted with a falling object protection system. When selecting the type of vehicle to be used, consideration must be given to:

- the type of material to be lifted;

- its weight;

- type of stack being constructed; and

- the distance to be reached.

- The vehicle should be able to deal with a stack that has collapsed or bales that have fallen. Vehicles must be fitted with warning devices and have visual aids to reduce blind spots on the vehicle.

- Routine visual inspections of stacked bales should be conducted and recorded to identify any slippage/movement.

Training and instruction

- Ensure that the risk assessment and control measure are brought to the attention of the employees.

- Ensure that drivers and other machine operators are competent and have appropriate training for the type of vehicle, and lifting attachments being used.

- Ensure that employees receive information, instruction, training and supervision on how to deal with stacks that have become unstable.

- Ensure that employees have training on fire and emergency procedures.